Automatic Palletizer

-

fully automatic barrels divider machine

Fully automatic divider barrels machine

The stacked barrels are divided and feeds to the filling line at one time according to filling needs.

Adavantage- vertical bucket divider small, greatly saves space.

- Divider from bottom bucket ,so accurate and fast.

- it comes with a double lift handle device to avoid hanging buckets efficiency.

Parameter

Product itemtechnical parameterDimensions (L*W*H) mm

2000*1300*2700

bucket speed10-18 barrels/min

Applicable Specifications

18-25L wide mouth drumBucket success rate

≥99.7%mains power220V/50Hz;1.5KWAir pressure0.6MPa -

Servo Palletizer MD-01 automatic Intelligent robot

1. Pick up one/multiple products;

2. It can be mixed with multiple models, sizes, and shapes, and can be easily picked up by one machine.

3. Simple operation, unmanned operation improves work efficiency. -

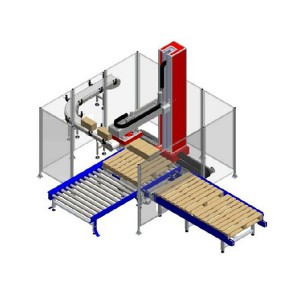

MD-01L Rotary Servo Palletizer

●This machine is composed of Z, X, Y axis and gripper to form a single-column palletizing main system.combined with an automatic pallet feeder, palletizing conveyor line, and in-out conveyor line to form a full-automatic palletizing system;

● Mitsubishi PLC+touch screen control, intelligent operation management, simple and easy to master;

●300 degree rotating double palletizing ultra-high servo palletizer -

MDJ Fully Automatic Manipulator Palletizer

1. Multifunctional: carton erector/filling/palletizing, taking into account multiple functions at the same time.

2. Complex models, multiple sizes, multiple models, free switching, the best choice for scenes with more complex requirements.

3. Easy to operate and save manpower.

4. A variety of configurations are available. We have rich on-site experience and can customize solutions according to different scenarios. -

MD Fully automatic mechanical palletizer

The palletizer is to stack the cartons, turnover baskets, and packaging bags that have been loaded into the products on the pallet in a certain arrangement for automatic stacking. It can stack multiple layers and then output, which is convenient for forklifts to transport to the warehouse for storage.

-

Stacker MD-09 suitable for assembly line

After the forklift puts the empty pallet on the conveyor, the cylinder of the left and right mechanism of the horizontal plate moves to insert the second pallet at the bottom, and then the lift cylinder rises to lift the second and above pallets, and the bottom pallet is transported out.